About Nano Dimension

Nano Dimension’s (Nasdaq: NNDM) vision is to transform the

electronics and similar additive manufacturing sectors into an environmentally friendly & economically efficient additive manufacturing Industry 4.0 solution, while enabling a

one-production-step-conversion of digital designs into functioning devices - on demand, anytime, anywhere.

Nano Dimension plans to execute on this vision by building an ecofriendly and intelligent distributed network of additively manufacturing self-learning & self-improving systems, which are designed to deliver a superior ROI to their owners as well as to Nano Dimension shareholders and stakeholders.

The DragonFly LDM® 3D printing systems serve cross-industry High Performance Electronic Device s ( Hi-PEDs®) fabrication needs, by depositing proprietary conductive and dielectric materials simultaneously, while concurrently integrating in-situ capacitors, antennas, coils, transformers, and electromechanical components. The outcomes are Hi-PEDs® which are integral enablers of autonomous intelligent drones, cars, satellites, smartphones, and in vivo medical devices. These products enable iterative development, IP safety, fast time-to-market, and device performance gains. With DragonFly LDM®, a revolution happens at the click of a button, allowing customers to go from CAD to a functional device in a matter of hours instead of weeks; creating products with better performance; reducing the size and weight of electronic parts and devices; enabling innovation; and, critically important, protecting IP, all the while limiting environmental pollution and chemical waste.

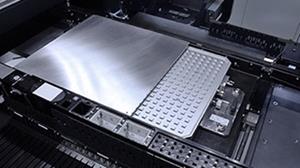

Nano Dimension’s Fabrica 2.0 micro additive manufacturing system enables the production of microparts based on a Digital Light Processor (DLP) engine that achieves repeatable micron levels resolution. The Fabrica 2.0 is engineered with a patented array of sensors that allows a closed feedback loop, using proprietary materials to achieve very high accuracy while remaining a cost-effective mass-manufacturing solution. It is used in the areas of micron level resolution of medical devices, micro-optics, semi-conductors, micro-electronics, micro-electro-mechanical systems (MEMS), micro fluidics and life sciences instruments.

For more information, please visit www.nano-di.com.

Forward Looking Statements

This press release contains forward-looking statements within the meaning of the “safe harbor” provisions of the Private Securities Litigation Reform Act of 1995 and other Federal securities laws. Words such as “expects,” “anticipates,” “intends,” “plans,” “believes,” “seeks,” “estimates” and similar expressions or variations of such words are intended to identify forward-looking statements. For example, Nano Dimension is using forward-looking statements in this press release when it discusses the potential benefits to Nano Dimension of the acquisition of Essemtec, the potential benefits of ESSEMTEC’s products and their ability to enhance Nano Dimension’s products, the potential for additional payments to ESSEMTEC’s shareholders, the ability of the merger of Nano Dimension’s and ESSEMTEC’s technologies to yield influence and momentum in the world of 3D printed electronics and assembly, the expectation that ESSEMTEC’s scientists and engineers and other team members will join Nano Dimension, the ability to leverage the distribution channels and go-to-market efforts of both organizations, the vision to merge the technologies of Nano Dimension’s micro-electronic 3D-fabrication machines for Hi-PEDs® with ESSEMTEC’s fuller suite of in-fabrication-process-equipment-assembly capabilities, the intention to use Nano Dimension’s deep learning based artificial intelligence technologies to become the “robotic brains” for Essemtec systems and the expectation that this will improve yield and throughput and drive a more seamless integration with Nano Dimension’s AME systems. Because such statements deal with future events and are based on Nano Dimension's current expectations, they are subject to various risks and uncertainties. Actual results, performance or achievements of Nano Dimension could differ materially from those described in or implied by the statements in this press release. The forward-looking statements contained or implied in this press release are subject to other risks and uncertainties, including those discussed under the heading “Risk Factors” in Nano Dimension’s annual report on Form 20-F filed with the Securities and Exchange Commission (“SEC”) on March 11, 2021, and in any subsequent filings with the SEC. Except as otherwise required by law, Nano Dimension undertakes no obligation to publicly release any revisions to these forward-looking statements to reflect events or circumstances after the date hereof or to reflect the occurrence of unanticipated events. References and links to websites have been provided as a convenience, and the information contained on such websites is not incorporated by reference into this press release. Nano Dimension is not responsible for the contents of third-party websites.

NANO DIMENSION INVESTOR RELATIONS CONTACT

Yael Sandler, CFO | ir@nano-di.com

U.S. Investor Relations:

Dave Gentry

RedChip Companies Inc.

Dave@redchip.com

407-491-4498 or 1-800-RED-CHIP (733-2447)

Attachments

- Fully Integrated Line Solutions and Highly Flexible Cell Solutions

- Cell Solution and Line Solution

- pic3

- pic4

- pic5