Enhanced Productivity, Collaboration and Product Data Management Help More than Three Million Users Harness the Emotive Power of Design to Create Powerful Experiences

VELIZY-VILLACOUBLAY, France — (BUSINESS WIRE) — September 21, 2016 — Dassault Systèmes (Paris: DSY) (Euronext Paris: #13065, DSY.PA), the 3DEXPERIENCE Company, world leader in 3D design software, 3D Digital Mock Up and Product Lifecycle Management (PLM) solutions, today announced the launch of SOLIDWORKS 2017. From small startups to global organizations, more than 3.1 million users can create multisensory experiences through innovative product design, with access to easy 3D design and development applications anytime, anywhere and on any device.

This Smart News Release features multimedia. View the full release here: http://www.businesswire.com/news/home/20160921005318/en/

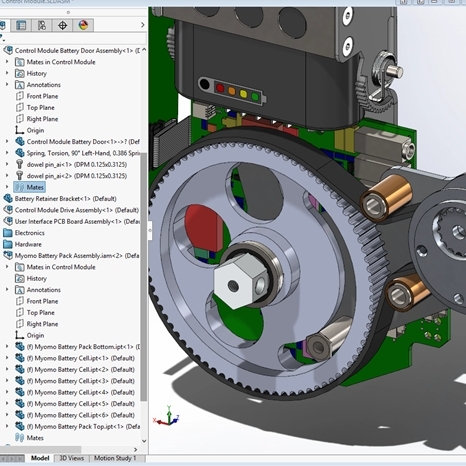

Dassault Systèmes' SOLIDWORKS 2017 3D design and development portfolio enhances designers' productivity, collaboration and product data management to create not just innovative products, but powerful experiences. SOLIDWORKS 2017 improves collaboration by unlocking new streamlined design workflows and removing barriers to third party data. Shown in the above image is SOLIDWORKS's 3D Interconnect, which allows users to work with both neutral and native CAD data. (Photo: Dassault Systèmes)

Powered by Dassault Systèmes’ 3DEXPERIENCE platform, SOLIDWORKS 2017 helps innovators design, validate, collaborate, build and manage their product development processes with integrated applications. SOLIDWORKS 2017 features more core power and performance, as well as new capabilities to address paperless manufacturing through the support of Model Based Definition, and printed circuit board (PCB) design. Both new and experienced users can improve productivity with simulation to analyze, solve, visualize and verify functionality of designs, before any prototype is created. New tools unlock any 3D model for better collaboration with vendors and customers, and dynamic product data management (PDM) from concept through to manufacturing allows for stronger support of multi-site and remote teams.

“We must fulfill a lot of medical device requirements, and SOLIDWORKS has been helpful for leveraging cutting-edge industrial design to get our work done faster and our myoelectric upper limb orthosis to market,” said Andrew Harlan, principal mechanical engineer, Myomo. “We exclusively use SOLIDWORKS for the full spectrum of our design work. The ability to collaborate with industrial designers, consultants and manufacturers across different time zones simplifies the whole process. The SOLIDWORKS models are so accurate and appealing that we can quickly design, iterate and improve a highly technical part.”

“SOLIDWORKS 2017 simplifies the design and development process with a better user experience, new capabilities for emerging technologies, and improved functionality for seamless collaboration with teams and networks,” said Gian Paolo Bassi, CEO, SOLIDWORKS, Dassault Systèmes. “Each year, our SOLIDWORKS community’s feedback drives our research and development to offer a flexible product portfolio for business, design and engineering needs. We are excited to put even more power and performance in their hands with SOLIDWORKS 2017.”

The following are some of the top user-requested features, new capabilities and enhancements included in the SOLIDWORKS 2017 portfolio:

Innovate by directly addressing PCB design:

- SOLIDWORKS PCB—seamlessly synchronize electronic and mechanical design on demand with a combination of electronics design expertise from Altium and ease of use from SOLIDWORKS.

- User-friendly interface—a unified environment for schematic and layout tools to select the best routing options based on design constraints with Interactive Routing, AutoRoute, Multi-Track, and Differential Pair, locate and select new components for informed decisions with real-time supplier data, and incorporate SOLIDWORKS models within the PCB design environment and verify electro-mechanical design intent.

Accelerate the design process with more core power and performance:

- Modeling power—speed up the design process with new tools for Chamfer, Fillet, and Advanced Hole Specification that create multiple variable chamfers in one simple operation, switch any pre-existing Chamfer to a Fillet and vice versa to apply design changes in seconds, capture and access previous hole definitions and apply pre-saved specifications in an instant, and construct stepped holes faster with one operation.

- Surfacing—remove obstacles to creating complex 3D geometry, save time and avoid complex workarounds with new surfacing features such as wrap, drag and drop, emboss, deboss, or 3D Curve.

- Magnetic mates—work with large, challenging assemblies by easily organizing equipment and space, publishing parts and assemblies as assets with appropriate connection points for easy drag and drop mating, and easy repositioning of models.

Validate design insights with simulation:

- Simulation static study—input parameters to automatically make logical decisions.

- Stress hot spots—quickly identify these to investigate a model or setup further simulation and verify results.

- Single-click conversion—instantly convert studies from linear static to non-linear or dynamic.

- RealView—display simulation results to clearly communicate analysis.

Improve collaboration by unlocking new streamlined design workflows and removing barriers to third party data:

- 3D Interconnect—work with both neutral and native CAD data, such as updating part and assembly files as design changes take place with the Update Model feature, directly opening imported files and treating them like Base Parts, or unlocking workflows from various sources to collaborate with customers and vendors.

- eDrawings—visualize all types of product design data for simple and accurate collaboration, from native CAD formats to 3D reality with Google Cardboard. Access product data anywhere with mobile apps for both Android and iOS devices.

Build and manage with data integration, from concept to manufacturing:

- SOLIDWORKS PDM—improve the way teams manage and collaborate on design by controlling design data and ensuring access to the right version. Enhance support for SOLIDWORKS MBD (model based definition) with auto-generated 3D PDFs, list native CAD files in the SOLIDWORKS PDM Vault check-in structure, and keep track of where they are used and overwrite versions to minimize clutter.

- SOLIDWORKS MBD—quickly and accurately communicate critical product information throughout downstream manufacturing operations with features such as basic dimensions and fully automated Polar Dimensioning Schemes, direct referencing of edges, easy creation of intersection geometry between drafted surfaces, and 3D PDF publishing at different accuracy levels for control over file size and quality.

For more information about SOLIDWORKS 2017, including product demonstrations and upcoming reseller events, please visit: solidworks.com/launch/index.htm?scid=SW2017_SWCOM_Innovate

About Dassault Systèmes

Dassault Systèmes, the 3DEXPERIENCE Company, provides business and people with virtual universes to imagine sustainable innovations. Its world-leading solutions transform the way products are designed, produced, and supported. Dassault Systèmes’ collaborative solutions foster social innovation, expanding possibilities for the virtual world to improve the real world. The group brings value to over 210,000 customers of all sizes, in all industries, in more than 140 countries. For more information, visit www.3ds.com.

3DEXPERIENCE, the Compass logo and the 3DS logo, CATIA, SOLIDWORKS, ENOVIA, DELMIA, SIMULIA, GEOVIA, EXALEAD, 3D VIA, BIOVIA, NETVIBES and 3DEXCITE are registered trademarks of Dassault Systèmes or its subsidiaries in the US and/or other countries.

View source version on businesswire.com: http://www.businesswire.com/news/home/20160921005318/en/

Contact:

Dassault Systèmes

Press:

Corporate / France

Arnaud

MALHERBE, +33 (0)1 61 62 87 73

Email Contact

or

North

America

Suzanne MORAN, +1 (781) 810 3774

Email Contact

or

EMEAR

Virginie

BLINDENBERG, +33 (0) 1 61 62 84 21

Email Contact

or

China

Grace

MU, +86 10 6536 2288

Email Contact

or

Japan

Yukiko

SATO, +81 3 4321 3841

Email Contact

or

Korea

Myoungjoo

CHOI, +82 10 8947 6493

Email Contact

or

India

Seema

SIDDIQUI, +91 1244 577 100

Email Contact

or

AP

South

Tricia SIM, +65 6511 7954

Email Contact