MONTREAL, April 01, 2024 (GLOBE NEWSWIRE) -- PyroGenesis Canada Inc. (http://pyrogenesis.com) (TSX: PYR) (OTCQX: PYRGF) (FRA: 8PY), a high-tech company (the “Company” or “PyroGenesis”) that designs, develops, manufactures and commercializes advanced plasma processes and sustainable solutions which are geared to reduce greenhouse gases (GHG) and address environmental pollutants, is pleased to announce its financial and operational results for the fourth quarter and the fiscal year ended December 31st, 2023.

“2023 was an interesting year for PyroGenesis, as we dealt with many of the issues associated with the growth and adoption of clean technology in a cautious economic environment,” said P. Peter Pascali, President and CEO of PyroGenesis. “We navigated cash management challenges brought about by higher costs associated with commercializing our technologies, continued inflationary pressures on material and labour costs, longer sales cycles for system sales caused by the uncertain economic environment we are all facing, and multiple requests from potential customers to help them in their investigation of using plasma as a solution to their many problems. As much of this type of work is new-use proof-of-concept, profit margins are negligible, and timelines imprecise.”

“While many of these efforts did not yield large contracts or system sales during the year, we cannot underestimate the impact these engagements have had and are having,” said Mr. Pascali. “In a few short years we have moved front-of-mind to many current and potential heavy industry customers who sought us out as they made their initial steps on their decarbonization journey. Since late 2019, when our work on the first tests of plasma in iron ore pelletization heralded our entry into the field of heavy industry decarbonization, the opportunities have expanded far beyond the one-furnace/one-industry concept, to numerous process heating steps in virtually every heavy industry. The array of opportunities possible within the aluminum industry alone has surpassed that of any one specific technology solution we offered in the past. This is a fundamental change that has taken hold in 2023 which I would suggest significantly de-risks PyroGenesis overall.”

Mr. Pascali added, “As the decarbonization trend continues to mature, we are well-positioned as a company with deep experience in the field – a key factor to customers as the scale of projects amplifies. This, along with our continued focus on cost optimization, our strong backlog of almost $29 million, negligible debt, the recent commercialization of our titanium metal powder production system, and a very robust sales pipeline, feeds my optimism for the future. As I have mentioned in the past, our revenue will fluctuate quarter to quarter, but our commitment will not. We are positioning ourselves to become a leader in heavy industry decarbonization technology solutions for many years to come.”

The information below represents important highlights from the past year, followed by an outline of the Company’s strategy and outlook for 2024.

2023 Q4 Production Highlights

The information below represents highlights from the past quarter for each of the Company’s main business verticals, followed by an outline of the Company’s strategy, and key developments that will impact the subsequent quarters.

In Q4 2023, PyroGenesis continued its focus on advancing its updated business strategy that was first outlined in the Company’s 2022 fourth quarter and year-end results.

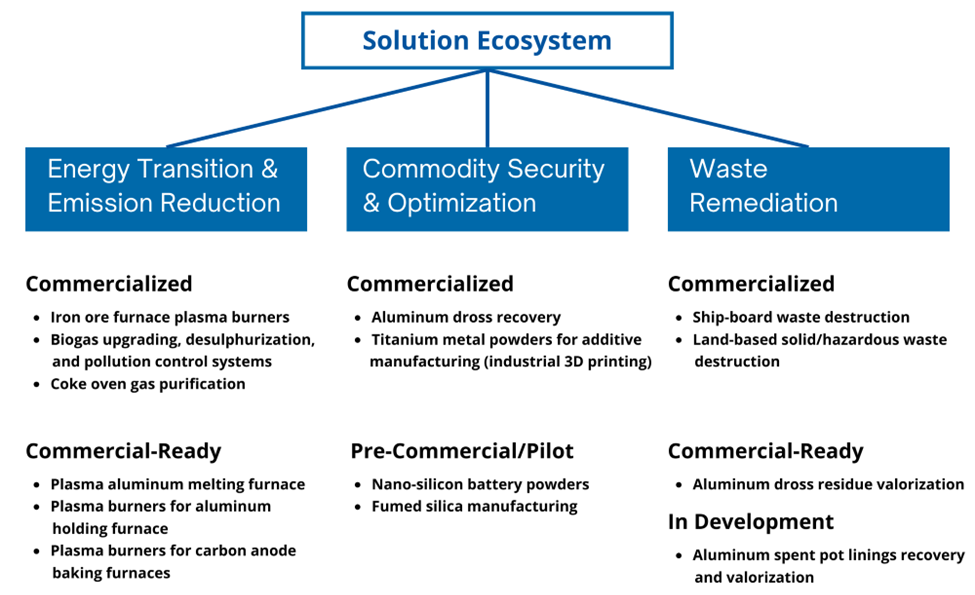

As noted, as the variety of uses for the Company’s core technologies has expanded, and industry interest has increased, the Company is concentrating its activities under a three tiered solution ecosystem that aligns with economic drivers that are key to global heavy industry:

Energy Transition & Emission Reduction:

- fuel switching, utilizing the Company’s electric-powered plasma torches and biogas upgrading technology to help heavy industry reduce fossil fuel use and greenhouse gas emissions,

Commodity Security & Optimization:

- recovery of viable metals, and optimization of production methods/processes geared to increase output, maximize raw materials and improve availability of critical minerals,

Waste Remediation:

- safe destruction of hazardous materials, and the recovery and valorization of underlying substances such as chemicals and minerals.

Within each vertical the Company offers several solutions at different stages of commercialization.

Commodity Security & Optimization

In October, the Company provided an update (Press Release dated October 3, 2023) on two projects: (i) the PUREVAP™ Quartz Reduction Reaction (“QRR”) pilot plant and (ii) the Fumed Silica Reactor (“FSR”) project.

For the QRR project – an initiative to create high purity silicon from quartz in a single step using a plasma reactor – the noteworthy progress and confirmations included:

- Completion of the scaling up of the QRR process by 2,500x from the previous laboratory scale, validating the original proof of concept.

- Demonstration of operation in a semi-continuous batch cycle.

- Production of silicon from quartz using a one-step direct carbothermal reduction process.

- 25% reduction in raw material use compared with conventional methods.

- Achievement of 3N+ (or 99.9+%) silicon purity, a crucial purity level for battery-grade silicon applications.

- Optimized QRR design for high performance during the tapping process, minimizing silicon contamination.

For the FSR project – an initiative to convert quartz into fumed silica in a single step using a plasma reactor – the Company announced that in a major step towards commercial-scale production, PyroGenesis had successfully deployed the FSR on a laboratory scale, resulting in the milestone production of fumed silica. Preliminary tests and analysis also confirmed that the material produced has chemical and physical characteristics compatible with those of commercially available fumed silica.