BOSTON & FREMONT, Calif. — (BUSINESS WIRE) — December 2, 2021 — Desktop Metal (NYSE: DM), a leader in mass production additive manufacturing (AM) solutions, and Uniformity Labs, a leading AM company revolutionizing industrial 3D printing materials and processes, today unveiled a partnership to qualify and deliver ultra-low porosity binder jetting powders that exhibit exceptional sintered part density and mechanical properties paired with Desktop Metal’s AM 2.0 binder jetting solutions.

This press release features multimedia. View the full release here: https://www.businesswire.com/news/home/20211202005553/en/

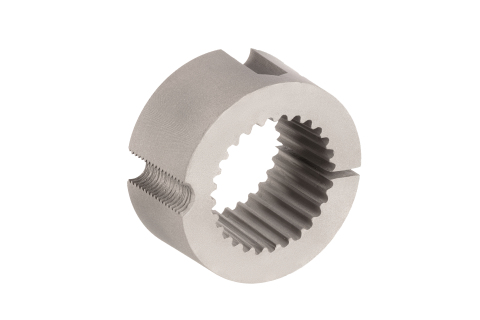

This strategic partnership leverages Desktop Metal’s high-speed binder jetting systems with Uniformity Labs’ innovative capabilities in metal powder processing to create industry-leading solutions that make it easier for businesses to adopt binder jetting to produce end-use metal parts at scale. The result is extraordinarily high precision parts exhibiting excellent material properties and surface finish, like this spline taper lock printed on the Shop System. (Photo: Business Wire)

Led by a team of world-leading materials scientists and 3D printing innovators, Uniformity Labs has developed patented materials technology that uniquely enables powders with tap densities up to 85 percent that sinter to full density and are significantly more flowable than powders of comparable size. These materials are unlike any other in their ability to repeatably spread uniformly across the print bed at the highest relative density, thereby delivering the highest attainable sintered part density with the lowest achievable part shrink in binder jetting. The result is extraordinarily high precision parts exhibiting excellent material properties and surface finish.

The goal of the partnership is to leverage Desktop Metal’s pioneering high-speed binder jetting systems and processes with Uniformity Labs’ innovative capabilities in metal powder processing to create industry-leading, integrated solutions that make it easier for businesses to adopt binder jetting to produce end-use metal parts at scale. The collaboration is focused on qualifying optimized binder jetting powders exclusively for Desktop Metal solutions, including the Production System™, Shop System™, and ExOne print platforms. Together, the companies are studying powder and binder interactions and will release print profiles with fully characterized mechanical properties for various materials, including stainless steels, nickel-based superalloys, and reactive metals such as aluminum.

To accelerate materials qualification and enhance collaboration between the companies, Uniformity Labs has installed several Desktop Metal systems at its facilities in Fremont, CA, including a Shop System and a Production System P-1. The partnership has already resulted in the qualification of several high-performance, engineered powders for Desktop Metal’s Shop System, which are commercially available to customers exclusively through Desktop Metal as part of its turnkey Shop System solution. Uniformity Labs topologically engineered powders for Desktop Metal’s Production System and ExOne platforms will be available directly through Uniformity Labs.

Uniformity Labs and Desktop Metal also previously announced a dedicated multi-year effort to develop aluminum 6061 for binder jetting that has produced a breakthrough unadulterated powder that sinters to better than wrought yield strength and ultimate tensile strength with excellent elongation. The companies plan to continue to work together to qualify the aluminum 6061 powder on Desktop Metal’s Production System platform and scale production for commercial release.

“We are excited to unveil this strategic partnership with Uniformity Labs, which is pioneering materials solutions that will advance the AM industry,” said Ric Fulop, Founder and CEO of Desktop Metal. “Binder jetting powders processed with Uniformity Labs technology enable unmatched mechanical properties and can further improve the economics of printing. We look forward to collaborating with the Uniformity Labs team to optimize binder jetting powders exclusively for Desktop Metal’s AM 2.0 solutions and provide our customers with integrated offerings including hardware, software, and materials that enable robust adoption of AM for mass production.”

“This partnership strengthens our ongoing collaboration with Desktop Metal to provide incredible value for its customers looking to adopt next-generation AM solutions,” said Adam Hopkins, Founder, and CEO of Uniformity Labs. “We are thrilled to continue our work with Desktop Metal to qualify our high-performance, engineered powders that deliver superior mechanical properties, surface finish, and part reliability.”

About Desktop Metal

Desktop Metal, Inc., based in Burlington, Massachusetts, is accelerating the transformation of manufacturing with an expansive portfolio of 3D printing solutions, from rapid prototyping to mass production. Founded in 2015 by leaders in advanced manufacturing, metallurgy, and robotics, the company is addressing the unmet challenges of speed, cost, and quality to make additive manufacturing an essential tool for engineers and manufacturers around the world. Desktop Metal was selected as one of the world’s 30 most promising Technology Pioneers by the World Economic Forum, named to MIT Technology Review’s list of 50 Smartest Companies, and the 2021 winner of Fast Company’s Innovation by Design Award in materials and Next Big Things in Tech Award for sustainability. For more information, visit

www.desktopmetal.com.

About Uniformity Labs

Uniformity Labs develops breakthrough material and software solutions to accelerate and expand global commercial/industrial 3D printing (AM) markets. Its patented technology uniquely enables groundbreaking improvements in throughput and reductions in residual stress across materials and platforms in laser powder bed fusion printing. In binder jetting, Uniformity powders deliver fully dense parts with minimal sintering shrink, resulting in the ability to manufacture to otherwise unobtainable high precision, material mechanical properties, and part surface roughness. Uniformity’s feedstock materials and print processes dramatically impact the AM value chain by increasing the reliability and efficiency of printing. For more information, please visit

www.uniformitylabs.com.

Forward-looking Statements

This press release contains certain forward-looking statements within the meaning of the federal securities laws. Forward-looking statements generally are identified by the words “believe,” “project,” “expect,” “anticipate,” “estimate,” “intend,” “strategy,” “future,” “opportunity,” “plan,” “may,” “should,” “will,” “would,” “will be,” “will continue,” “will likely result,” and similar expressions. Forward-looking statements are predictions, projections, and other statements about future events that are based on current expectations and assumptions and, as a result, are subject to risks, uncertainties. Many factors could cause actual future events to differ materially from the forward-looking statements in this document, including but not limited to, the risks and uncertainties set forth in Desktop Metal, Inc.'s filings with the U.S. Securities and Exchange Commission. These filings identify and address other important risks and uncertainties that could cause actual events and results to differ materially from those contained in the forward-looking statements. Forward-looking statements speak only as of the date they are made. Readers are cautioned not to put undue reliance on forward-looking statements, and Desktop Metal, Inc. assumes no obligation and does not intend to update or revise these forward-looking statements, whether as a result of new information, future events, or otherwise.

View source version on businesswire.com: https://www.businesswire.com/news/home/20211202005553/en/

Contact:

Media Relations:

Caroline Legg

carolinelegg@desktopmetal.com

(203) 313-4228

Frank De Maria

frank.demaria@purposefulcommunications.com

(347) 647-0284

Investor Relations:

Jay Gentzkow

jaygentzkow@desktopmetal.com

(781) 730-2110