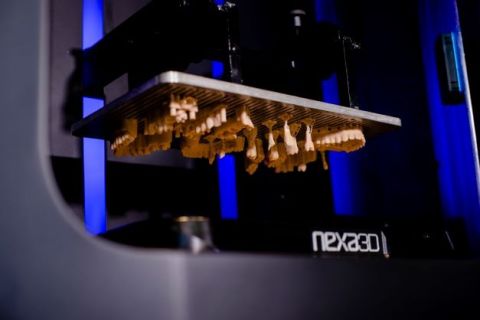

VENTURA, Calif. — (BUSINESS WIRE) — July 27, 2021 — Nexa3D, the maker of ultrafast polymer 3D printers, today announced the immediate commercial availability of xMODEL 2505 dental material powered by BASF Forward AM. This rigid beige color material is ideal for the ultrafast production of additively manufactured thermoformed dental models, dental removable dies, and other dental model applications. xMODEL 2505 printed on Nexa3D’s NXD 200 3D printer delivers higher print accuracy that brings the total cost per model down for dental prosthetics manufacturers by reducing their printing, post-processing, and fitting time. This new dental model material requires no finishing detergents, as the printed models can simply be washed with water.

This press release features multimedia. View the full release here: https://www.businesswire.com/news/home/20210727005821/en/

xMODEL 2505 (Photo: Business Wire)

To learn more about Nexa3D dental capabilities, check out this media kit and watch this video.

Nexa3D’s collaboration with BASF Forward AM leverages their combined capabilities to deliver faster additively manufactured dental solutions for dental labs leveraging the 20X productivity advantage of its ultrafast NXD 200 dental 3D printer. No other manufacturing process offers as many possibilities for faster dental lab model fulfillment. Combining Nexa3D’s productivity with Forward AM’s tailor-made materials makes it possible for dental labs to optimize their dental model production, taking advantage of a material that delivers robust processing and excellent model accuracy and detail.

“Our extended partnership with Nexa3D enables us to develop a broad range of photopolymers for the most lucrative and fastest-growing segment in digital dentistry,” explained Francois Minec, Managing Director, BASF 3D Printing Solutions. “Together, we plan to deliver an expanded materials library across Nexa3D’s rapidly growing portfolio of photoplastics (SLA) and thermoplastics (QLS) for the benefit of our customers around the globe.”

“For dental labs and prosthetics manufacturers that are competing for higher share, based on service levels, fast just got faster thanks to BASF’s new generation of dental materials,” said Kevin McAlea, COO of Nexa3D. “Both companies are committed to democratizing access to additively manufactured dental, industrial and consumer products at scale. With NXD 200 dental printers’ 20X productivity gains, and up to 85 percent lower total cost of ownership, dental labs can now access higher productivity, better functionality, and exceptional cost effectiveness.”

The xMODEL 2505 is available through Nexa3D’s growing network of resellers. Contact us to find a reseller near you, or to schedule your live 3D printing demo today via Zoom. For more information about Nexa3D and its high performance 3D printing materials, visit nexa3d.com, like on Facebook, or follow on Instagram, Twitter, and LinkedIn.

About BASF 3D Printing Solutions

BASF 3D Printing Solutions GmbH, headquartered in Heidelberg, Germany, is a 100% subsidiary of BASF New Business GmbH. It focuses on establishing and expanding the business under the Forward AM brand with advanced materials, system solutions, components, and services in the field of 3D printing. BASF 3D Printing Solutions is organized into startup-like structures to serve customers in the dynamic 3D printing market. It cooperates closely with the global research platforms and application technologies of various departments at BASF, and with research institutes, universities, startups, and industrial partners. Potential customers are primarily companies that intend to use 3D printing for industrial manufacturing. Typical industries include automotive, aerospace, and consumer goods. For further information please visit www.forward-am.com.

About BASF

At BASF, we create chemistry for a sustainable future. We combine economic success with environmental protection and social responsibility. More than 110,000 employees in the BASF Group contribute to the success of our customers in nearly all sectors and almost every country in the world. Our portfolio is organized into six segments: Chemicals, Materials, Industrial Solutions, Surface Technologies, Nutrition & Care, and Agricultural Solutions. BASF generated sales of €59 billion in 2020. BASF shares are traded on the stock exchange in Frankfurt (BAS) and as American Depositary Receipts (BASFY) in the U.S. Further information at www.basf.com

About Nexa3D

Nexa3D is passionate about digitizing supply chain sustainably. The company makes ultrafast polymer 3D printers, that deliver 20X productivity advantage, affordable for professionals and businesses of all sizes. The company's photoplastic printers are powered by its proprietary Lubricant Sublayer Photo-curing (LSPc) and its thermoplastic printers are powered by Quantum Laser Sintering (QLS). The company’s partnerships with world-class material suppliers unlock the full potential of additively manufactured polymers for volume production. The company’s NexaX proprietary software platform optimizes the entire production cycle through process interplay algorithms to ensure part performance and production consistency, while minimizing material usage and waste, reducing energy and carbon footprints. For more information, please visit www.nexa3d.com.

View source version on businesswire.com: https://www.businesswire.com/news/home/20210727005821/en/

Contact:

BASF 3D Printing Solutions

Lisa Krämer

Ph: +49 6221 67417-30

media@basf-3dps.com

Nexa3D

Leah Elston-Thompson or Martin Deakin

Ph: +44 (0) 1785 225416

e-mail:

leah@stonejunction.co.uk or

martin@stonejunction.co.uk

Ref: NED027/07/21