- Thanks to high-performance thermoplastic resin and ABS-M30i biocompatible 3D printing material, UPSA is now able to replace metal parts in some applications and reverse engineer components for part replacement

- Creation of lightweight 3D printed parts decreases part weight by 70 percent, which reduces machine wear-and-tear, in turn extending productivity and machine longevity

MINNEAPOLIS & REHOVOT, Israel — (BUSINESS WIRE) — March 27, 2018 — Stratasys (NASDAQ: SSYS), a global leader in applied additive technology solutions, has announced that leading French pharmaceuticals company, UPSA, is reinvigorating its manufacturing workshop and enjoying cost reductions of as much 95 percent on some processes, since integrating Stratasys additive manufacturing. The impact on UPSA’s operations has been immediate and positive, with the investment paying for itself within just one year of arrival.

This press release features multimedia. View the full release here: https://www.businesswire.com/news/home/20180327005683/en/

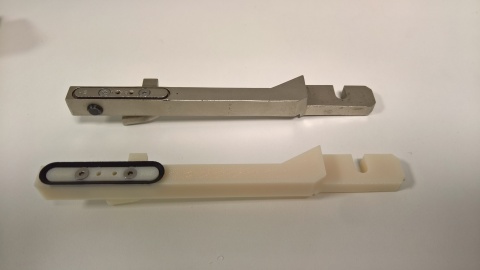

UPSA is making 95 percent cost reduction on one part alone, by replacing cast steel arms with high-performance 3D printed arms using ABS-M30i 3D printing material (Photo: Business Wire)

The company, which is owned by Bristol-Myers Squibb, identified additive manufacturing as a means to revitalize its in-house workshop and attract the next generation of technicians. UPSA also sees the technology as the key to overcoming production-line challenges, which had previously limited the number of machine parts it was able to make via traditional manufacturing methods.

“We identified 3D printing as a possible solution to our needs and made an estimate of all the parts we could 3D print to see if we could save manufacturing costs and reduce our stock of parts,” explains Mathieu Dumora, Project Manager in UPSA’s Technical and Infrastructure Department. “We quickly realized that by using 3D printed parts, we could reduce part weight by 70 percent, which reduces machine wear-and-tear, and has a big impact on productivity and machine longevity.”

Ninety-five percent cost reduction on just one part alone

This positive evaluation led to UPSA’s investment in a Stratasys Fortus 450mc™ Production 3D Printer, which proved an immediate success by quickly delivering substantial efficiency savings for the company not least in the area of critical parts replacement, which, as Dumora explains, was a key priority.

“One machine in our manufacturing and packaging line is a heavy cast steel arm, used as part of the operation to grip and suction open a folding carton, so that blister packs can be inserted,” he explains.

“These arms are heavy, can become distorted, and sometimes fail and break the machine, but using a 3D printed arm is safer. The ABS-M30i biocompatible 3D printing material can recover if it distorts, but if it breaks, it’s a minimal cost and a short printing time to replace. That’s a huge improvement over a costly steel one. In one year alone, we produced 55 of these parts and made a 95 percent cost reduction on each.”

Additive manufacturing helps replace time-consuming and expensive visual inspections

UPSA also uses its Fortus 450mc Production 3D Printer to build a device to improve the safety of the closure caps for its Efferalgan (paracetamol) for children, after some caps were received from the supplier with particles that could have inadvertently posed a risk of contamination to the medication. The device has proven so successful that UPSA has been able to discontinue the time-consuming and expensive visual inspections that were previously deployed.

“We developed a system that sucks and blows air to remove any particles,” says Dumora. “We test the air suctioned, and even sometimes place particles in caps to test efficacy. Thanks to additive manufacturing, we are able to make this solution ourselves and evolve it through development iterations quickly and cost-effectively.”

Part consolidation contributes to huge first-year savings

UPSA is also witnessing significant savings thanks to its deployment of Stratasys additive manufacturing for the production of camera mounts on the manufacturing line.

“We apply track-and-trace coding to our packaging, and to ensure these are being properly printed, a camera is mounted above each one,” explains Dumora. “One of our design engineers used the Fortus 450mc to create the shape he needed, before using it to make 22 units – one for each machine. Prior to this innovation, an assembly of 27 parts was needed; the new design has just two parts, which has seen us enjoy a significant reduction in production time and cost.”

“Needless to say, for those of us who use it, the Fortus 450mc is an

absolute work-horse, but it’s immediate and positive impact is

ultimately underscored by the fact that in the first year of integrating

the machine, we more than made a return on our investment,” concludes

Dumora.