Company announces largest presence ever at EuroMold 2014 with three exhibits spanning 20 customer applications

Stratasys unveils new Professional Services program and new key partnerships

11 new products premier at EuroMold

MINNEAPOLIS & REHOVOT, Israel — (BUSINESS WIRE) — November 25, 2014 — Stratasys Ltd. (Nasdaq: SSYS) is demonstrating at EuroMold 2014 (Frankfurt, Germany, Nov. 25-28) its additive manufacturing ecosystem, which gives designers, engineers and manufacturers heightened flexibility to 3D print prototypes, parts and final end-use products ‘their way.’

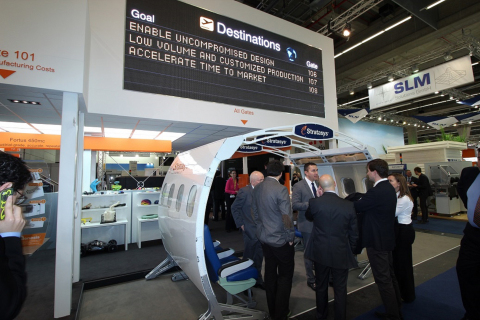

Full-size airplane cabin with interiors created using unique combinations of Stratasys FDM and PolyJet 3D printing technologies. (Photo: Stratasys)

Stratasys is bringing its additive manufacturing ecosystem to life at EuroMold 2014 with new partnership and program announcements, recently introduced 3D printers and materials, and a host of new show-stopping customer applications that exemplify faster time to market, reduced costs, customized mass production, and improved design.

20 Game-Changing 3D Printed Customer Applications Plus Newly Announced 3D Printers and 3D Production Systems Span Three Stands at EuroMold 2014

At its main booth, Hall 11, stand D90, visitors can get an up-close insight into superior workflow and cost-reducing capabilities for designers and manufacturers. The aerospace-themed stand features a remarkable, full-size airplane cabin interior that employs a combination of state-of-the-art FDM and PolyJet 3D printing techniques for prototypes (various seat parts), manufacturing tools (sand casting pattern for seat base) and end-use parts (sidewall upper skin, electrical clips and air ducts).

Aviation is just one of the application solutions that Stratasys is presenting in Hall 11. Kiosks located throughout the booth highlight a wide range of strategic customer applications, including:

- StreetScooter (Aachen University, Germany) an affordable and sustainable fully functional prototype electric car designed and built in just one year with the Stratasys Objet1000 – the world’s largest multi-material 3D production system.

- Normal (USA) perfectly demonstrating mass customization production by 3D printing custom-fit earphones using Fortus 250mc 3D Printers.

- Eletro Zagonel (Brazil) controlled design confidentiality and accelerated time-to-market for their superior shower system by producing functional shower prototypes in-house using the Objet30 3D Printer.

- Legacy Effects (USA) creating “impossible to build” costumes and final props for Hollywood blockbuster movies like “IronMan” and “RoboCop” using Stratasys 3D Printers.

In addition, at the Molding and Tooling Hall 8, stand H139, Stratasys is showcasing the significant efficiencies achievable today by integrating additive manufacturing into traditional manufacturing processes. Five core manufacturing applications are being featured: jigs and fixtures, composite processing tooling, metal processing tooling, plastic processing tooling, and end-use products - with examples such as a Porsche engine with carbon fiber parts and robotic end of arm tools.

Demonstrating how creatives are pushing the boundaries of 3D printing, Stratasys is offering EuroMold visitors a chance to view 12 stunning 3D printed sculptures by three influential artists in a special gallery in Hall 11, stand FN01. Entitled “The Sixth Element: Unveiling the Beauty of 3D Printing,” the gallery features 12 ground-breaking new works by Professor Neri Oxman, Nick Ervinck and Eyal Gever.

“3D printing is no longer just about the systems themselves,” says David Reis, chief executive officer of Stratasys. “The industry has reached a new level of maturity and sophistication that demands a holistic, collaborative approach to additive manufacturing, giving our customers access to full solutions that address all their requirements and the flexibility to leverage 3D printing their way. At EuroMold 2014, we are introducing our additive manufacturing ecosystem through an advanced fleet of 3D printers and materials, a host of unique customer applications, our new Professional Services program, and several key partnerships that drive 3D printing optimization and accessibility.“

Premier of Newly-Announced High-Performance 3D Printers and 3D Production Systems

EuroMold 2014 sees the premier of Stratasys recently-announced 11

high-performance 3D printers and materials. With the launch of the

popular

Objet500

Connex3 earlier this year, Stratasys introduced its unique

triple-jetting technology that began a new era in color multi-material

3D printing. Six new

PolyJet-based

3D printers employing triple-jetting technology cross-platform allow

designers and workgroups to cost-effectively produce prototypes, tools,

injection molds and end-use parts featuring vivid color and outstanding

product realism. The Objet260 Connex1, 2 and 3 series, which is a

compact and office friendly platform, and the Objet350 Connex1, 2 and 3

series that deliver the same capabilities with larger build sizes.