-Realizes small package by adopting high-voltage process of 80V (absolute maximum rating)-

TOKYO — (BUSINESS WIRE) — August 7, 2014 — Toshiba Corporation (TOKYO:6502) today announced the launch of TB67S158, a dual unipolar motor driver IC for stepping motors. Sample shipments start today, with mass production scheduled to start in October.

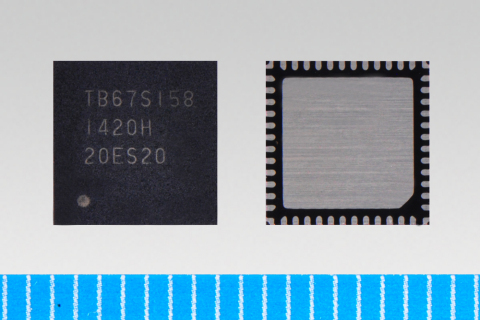

Toshiba: dual unipolar stepping motor driver IC "TB67S158FTG" (Photo: Business Wire)

The number of motors and driver ICs required in products including amusement machines, home appliances and industrial equipment, is growing. On top of this, manufacturers are being asked to downsize equipment to save space and cut energy consumption. As a result, driver ICs are increasingly expected to play multiple roles in driving motors.

Toshiba’s current driver IC “TB67S149” can control only one unipolar motor, but the new “TB67S158” can support dual motor control by incorporating an 8ch-MOSFET. For example, by setting the output to the constant voltage control mode, 4ch-outputs can control the motor while the other 4ch can control the other motor. With this capability, “TB67S158” can be applied to various equipment and meet diverse requirements.

Incorporating a monolithic package structure [1] using Toshiba’s latest analog high-voltage process (80V) has realized both a small, high-radiation, surface-mounting type package (QFN) and lead-inserting type package (SDIP) for flow mounting. This package line-up meets various requirements for space-saving equipment and support part reductions toward downsizing the equipment.

Main features of the new product

-

Dual unipolar

The “TB67S158” incorporates 8ch-MOSFET outputs to control dual unipolar motors simultaneously. -

Monolithic structure

Incorporates monolithic structure by adopting the latest analog high-voltage process (BiCD 130nm, 80V). This reduces the mounting space and number of parts, compared with that of control circuits based on transistor arrays, and so on. -

Selection of two types of packages according to application

Surface-mounting type QFN package, best suited for downsizing of the module and set, and mounting type SDIP package for flow mounting, can be selected. -

Built-in error detection circuit

The TB67S158 incorporates thermal shutdown circuit and overcurrent shutdown circuit. Higher equipment safety and reliability are maintained by outputting ERR signal in operation.

Applications

Amusement machines such

as pachinko and video slot machines; home appliances such as

refrigerators and air conditioners; industrial equipment including

banking terminals, office- and factory-automation equipment.

|

Main Specifications of the New Product |

||||

| Product name | TB67S158FTG | TB67S158NG | ||

| Control I/F |

Parallel input

Serial input CLK input |

Parallel input

Serial input |

||

|

Absolute maximum

|

80V, 1.5A (Normal mode)

3.0A (Large mode) |

80V, 1.5A (Normal mode) | ||

| Package | QFN48 | SDIP24 | ||

| Other features |

Built-in error detection circuits (thermal shutdown circuit and

|

|||